Aluminium fenestration system providers supply products in either powder coated finishes or anodized finishes. But the profile preperation and performance class of powder can have implications on your product Warranty !!!

Aluminium is a fantastic product for fenestration products. Once having a reputation of being cold and commercial, aluminium fenestration technology has come on leaps and bounds and comes with many benefits including:

- The stability of aluminium profiles allows for minimal frame thicknesses, narrow profiles, larger constructions and is better suited for demanding applications.

- Developments in thermal break materials and their design mean aluminium system’s thermal performance is now on par with PVC and Timber.

- Aluminium systems have a fantastic appearance and are well suited to todays modern and minimalist building designs.

Many people when ordering aluminium are focused on colour and texture only and may not be aware of the profile preperation and performance class of powder options available. In most cases if not questioned many suppliers will by default assume a standard finish (policies may differs depending on manufacturer). In most cases standard RAL in a matt finish with basic profile preparation and a class 1 powder.

So lets look at some of the options available regarding grade of finishes:

Powder coating:

Profile preparation (aluminium profiles before powder coating are chemically degreased / etched)

Profile preparation standard – Degreasing & etching =>1g/m²

Profile preparation enhansed – Degreasing & etching =>2g/m² (commonly applied for costal areas or more aggresive environments)

Pre-anodization

For more aggressive environments and closer costal proximity some system providers are anodizing the profile before powder coating. This gives the profile a double layer of protection.

Epoxy undercoat

Alternative to pre-anodization where an epoxy resin undercoat is applied to the profile prior to powder coating.

Powder classification

Powder is generally avalably in 3 classifications in accordance with the industry recognised testing institution Qualicoat. The classes identify the durability of the powder coating finish with regard loss of gloss through a given period of time. Class definitions can vary depending on weather/shade/matt/gloss but a fair simplified interpretation would be:

class 1 – loss of < 50% of gloss after 1 year

class 2 – loss of < 50% of gloss after 3 years

class 3 – loss of < 50% of gloss after 10 years

So which finish should you request for your product? Well it is essential to consult the guidance and warranty terms of the system provider.

Take for example Aluprof:

If we refer to ther guarantee the first thing we noted is the obligation is put on the buyer to inform Aluprof if the object is within 5km of the coast or in an agressive environment so they can specify an appropriate finish. So who is the buyer? Well in most cases the maufacturer or dealer should be aware of this and checking the instalation address he has assertained from the end client.

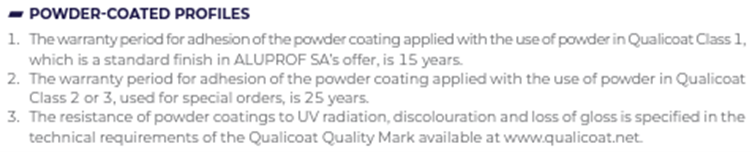

For adhesion Aluprof offer a 15 year warranty on a class 1 powder (non agressive environments) and a 25 year warranty on class 2 and 3 powders. But they refer UV resistance to Qualicoat standards – https://www.qualicoat.net/main/specifications.html

Other system providers follow similar patterns but exact details, requirements and conditions can differ. Some also put more emphasis on obligatory maintenance to be performed by the end client in accordance with the warranty terms.

For anodized only finish the process is similar and system providers will commonly offer a thicker anode layer for costal locations or aggressive environments.

So it’s important for all parties (manufacturers, dealers, installers and even end clients) to be sure the correct finish grade has been selected in accordance with the requirements of the system suppliers warranty. So we do not select a product inappropriate for the installation conditions that could eventually wave our rights to warranty.

For those in the USA it’s also worth noting that Reynaers has AAMA standards on its powder coating finishes available but this is a discussion for another post – https://www.reynaersus.com/news/choosing-the-right-color-for-your-windows-and-doors

Be vigilant !!!

Link to Aluprof Warranty: https://aluprof.com/files/downloads/gwarancja_2021_EN.pdf

Link to Reynaers Warranty: https://www.reynaers.com/sites/default/files/public/2023-03/REYNAERS-guarantee%202023-EN%20%281%29.pdf

Link to Qualicoat: https://www.qualicoat.net/main/home.html