I once had an experience with a company in Sweden who were installing PVC windows into pre-fabricated buildings. The window spec was precise identifying system provider and all details. The order was very attractive as there were a large quantity of identical windows. They would order from me but I had to be the cheapest. I worked the offer but no mater wvhat I tried I could not beat the competition. They was a small difference but enough for me to lose the job. So I went to my colleagues in R&D dept to see if they had any ideas.

I would have never considered their suggestion……..

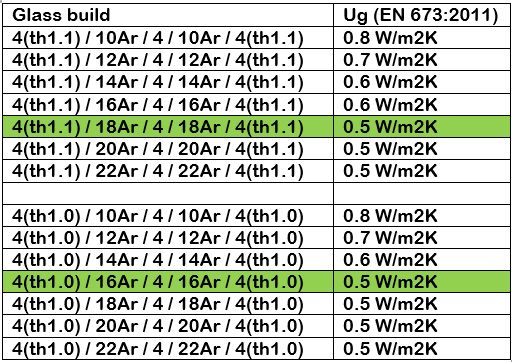

To meet the required Uw I had to achieve a Ug of 0.5W/m2K.

You will probably be aware of the term, low-e coating popular in the current eco-media synonymous with environmentally friendly windows. However not everyone may be aware there are two basic low-e coatings that are commonly used in the industry:

thermofloat 1.1

Offered under trade names:

- Euroglas – EN2plus

- SaintGobain – PLANITHERM XN

- Guardian Glass – ClimaGuard Premium2

- Pilkington – Optitherm S3

- AGC – iplus 1.1

Characteristics when applied to a typical triple glazed unit

Spec: 4(th1,1) 16Ar / 4 / 16Ar / 4(th1,1)

Ug (thermal properties) = 0.6 W/m2K

Tv (Light transmittance) = 73-74%

g (Solar factor – total solar energy transmittance= 52% – 53%

Cost = 61 EURO/m2 (suggested typical retail price)

thermofloat 1.0

Offered under trade names:

- Euroglas – ZERO NG

- SaintGobain – PLANITHERM ONE

- Guardian Glass – ClimaGuard 1.0

- Pilkington – Optitherm S1

- AGC – iplus 1.0

Characteristics when applied to a typical triple glazed unit

Spec: 4(th1,0) 16Ar / 4 / 16Ar / 4(th1,0)

Ug (thermal properties) = 0.5W/m2K

Tv (Light transmittance) = 56-65%

g (Solar factor – total solar energy transmittance = 36% – 43%

Cost = 68 EURO / m2 (suggested typical retail price)

Approximately 12% more expensive than thermofloat 1.1

So for the observant we quickly come to the following conclusions:

Considerations for thermofloat 1.1

+ Cheaper

+ Certainly preferable for our Northern European climate.

+ Solar factor is noticeably higher so we get more heat energy from the sun into our building

+ Beneficial for Passive house design as basic concept requires heating of the internal building fabric to act as a heat storage to carry us through he night.

+ Light transmittance is notably higher which is known to have a direct effect on human health.

– Lower thermal performance than thermofloat 1.0 ?

Considerations for thermofloat 1.0

+ Higher thermal performance than thermofloat 1.1 ?

+ Preferential for hotter climates where solar gain causes an overheating issue.

– More expensive

– Not so effective for passive house design

– Inside of the building will be darker as light transmittance is notably lower

So anyway, back to my conundrum…….

What did my personnel from R&D suggest?

“use thermofloat 1,1 and stick an 18mm spacer in there. Then you’ll get the same Ug=0.5W/m2K” (big smiles).

So yes, size does matter……..

Warm spacers typically offered in sizes: 10mm / 12mm / 14mm / 16mm / 18mm / 20mm / 22mm.

There are many factors that influence the selection of spacer bar size including the space a given system allows for the glass packet, the collective thickness of the panes used, objects inserted between glass panes (grids, blinds etc.) But as I learned it also has a bearing on thermal properties.

Now, lets firstly consider European norms (thermal properties)

Figures below calculated using EUROGLAS glaCE calculator.

Green noting the smallest glass packets achieving 0.5W/m2K.

The above may help you to make a better informed decision when selecting windows.